通富微电框架类封装

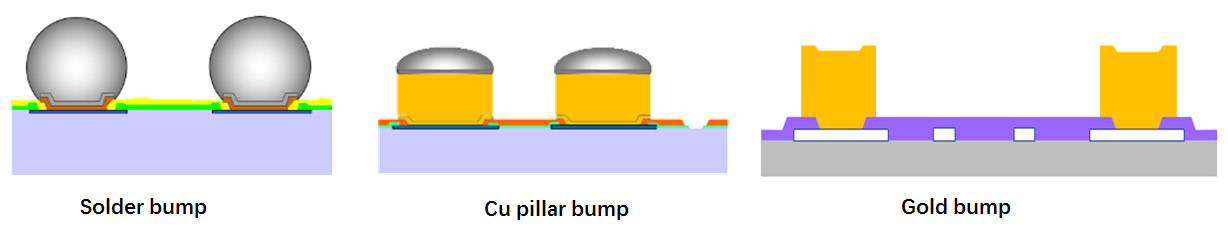

Production Overview ? ? ? ? TFME is able to provide Solder bump, Cu pillar bump and Gold bump for customer to meet different requirement. ? ? ? ? ? ? ? ???Solder bump? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??Cu pillar bump??? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??Gold bump ? ? ? ? ? ? ? ? - Wafer size: 8 inch / 12 inch?? ??? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- Wafer size: 8 inch / 12 inch? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? - Wafer size: 8 inch / 12 inch ? ? ? ? ? ? ? ? - Bump qty: 2892(MAX)? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- Bump qty:? 1500 pin (max)? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- Bump qty: 4091/pin (max) ? ? ? ? ? ? ? ? - Structure: 0P1M~2P2M? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? - Structure: 0P1M~1P2M? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? -?Structure: 0P1M~1P1MBump Series

? ? ? ? ? ? ? ? - Body size:? 0.7*0.76~10.7*10.7 mm? ? ? ? ? ? ? ? ? ? ? ?- Body size:? 1.0*1.5~10*10mm? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ??? - Structure: 0P1M~1P1M?

? ? ? ? ? ? ? ? - RDL L/S: min.5um/5um? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? ? ?- RDL? L/S: min. 5um/5um? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?? ?? - Bump L/S: min.10um/8um?

Solder bump & Cu pillar

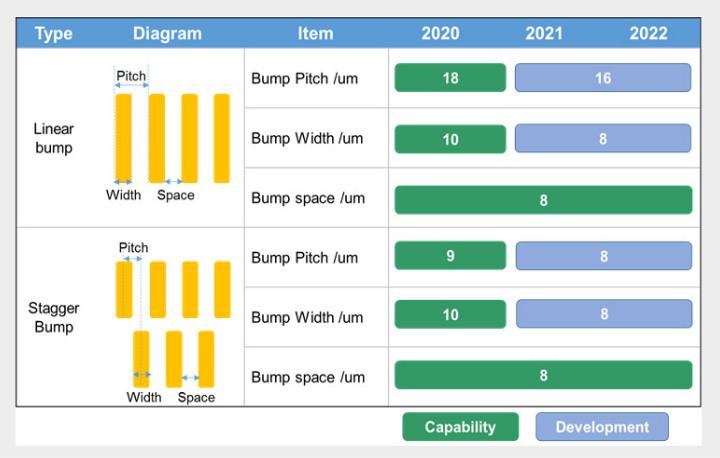

Process Capability & Design Rule

Gold bump

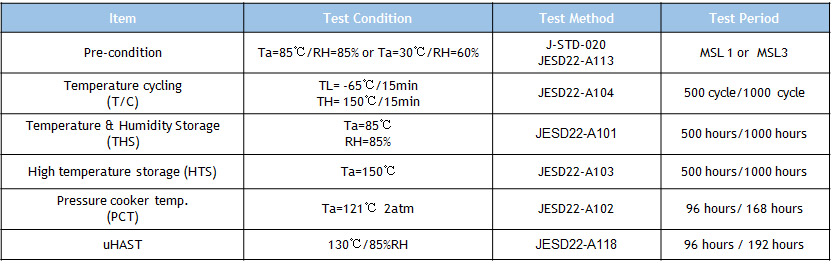

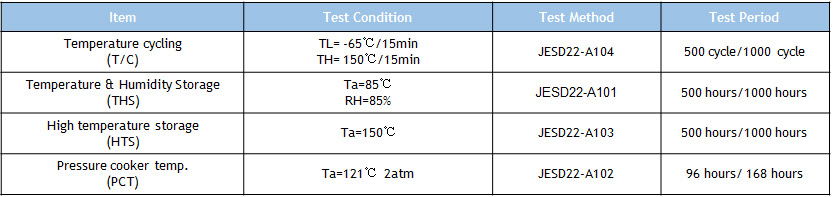

Reliability Test Standards

Solder bump & Cu Pillar bump

Gold bump

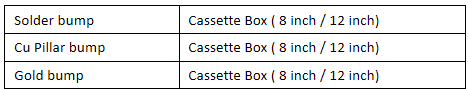

Shipment Packing

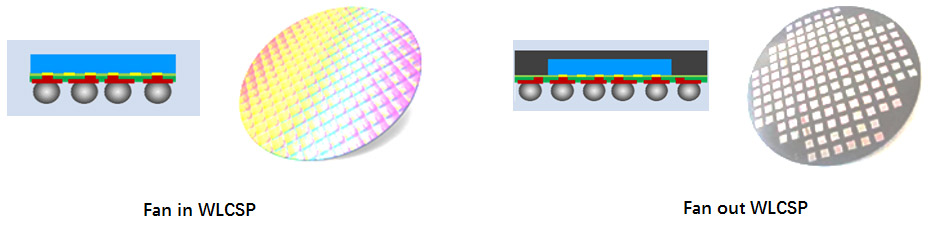

WLCSP Series

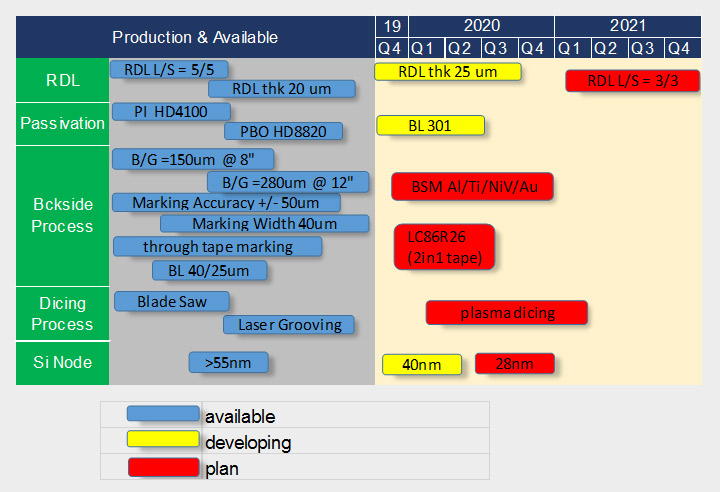

Production Overview

? ? ? ? TFME offers? various Wafer Level CSP product to customer including Fan in type and Fan out type.

Feature

? ? ? ? ? Fan in WLCSP? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?Fan out WLCSP

? ? ? ? ?- Ball count : 2~309? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? - Ball count : 36 ~203?

? ? ? ? ?- Structure: 1P1M~2P2M? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- Structure: 1P1M~3P3M

? ? ? ? ?- Body size:? 0.6*0.3~7.6*7.6mm? ?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- Body size: max 20*20mm

? ? ? ? ?- RDL L/S: min.5um/5um?? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ? ?- RDL L/S: min.2um/2um

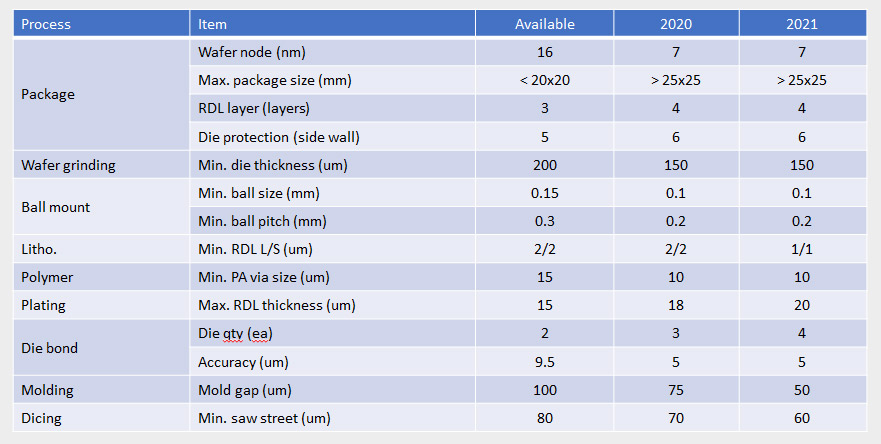

Process Capability & Design Rule

Fan in WLCSP

Process Capability & Design Rule

Fan out WLCSP

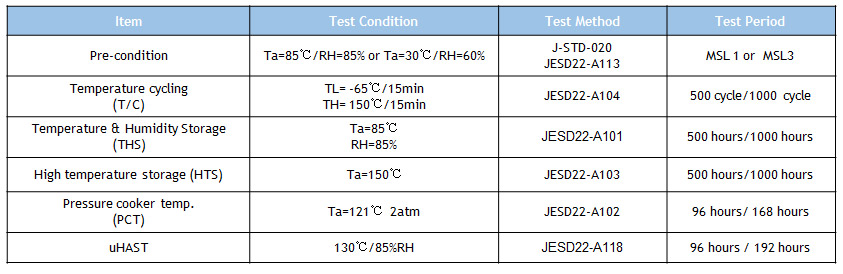

Reliability Test Standards

Shipment Packing

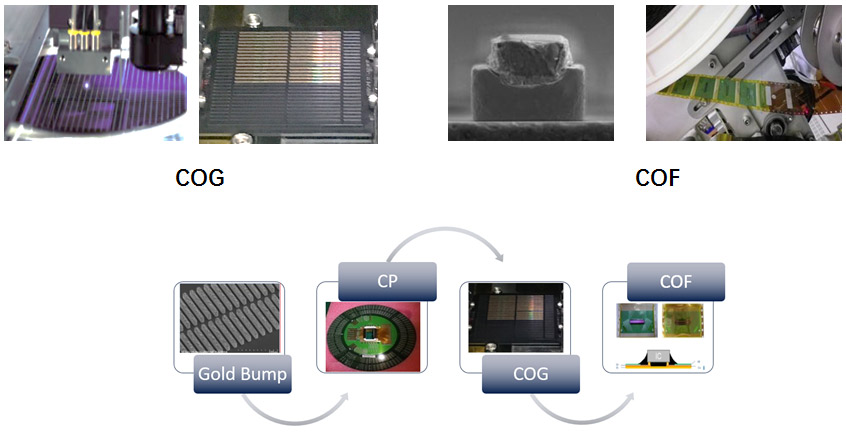

COGCOF Series

Production Overview

? ? TFME is able to provide COG (Chip On Glass) and COF (Chip On Film) services for gold bump drive IC?based on customer requirement.??

? ??

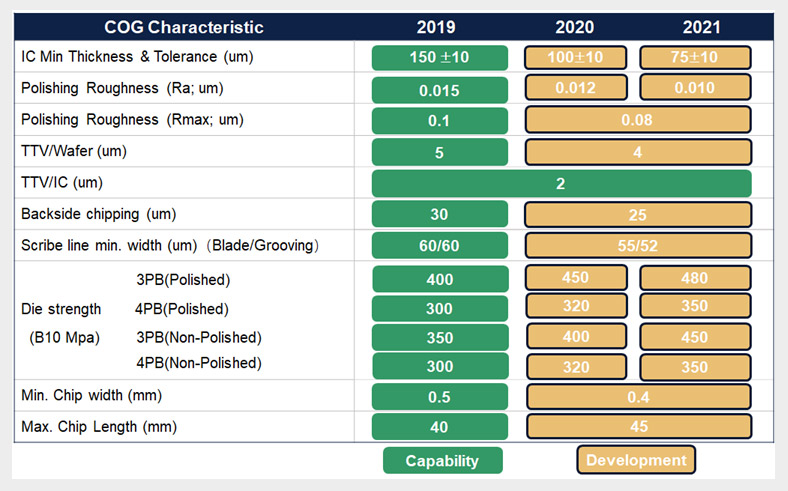

Process Capability & Design Rule

COG

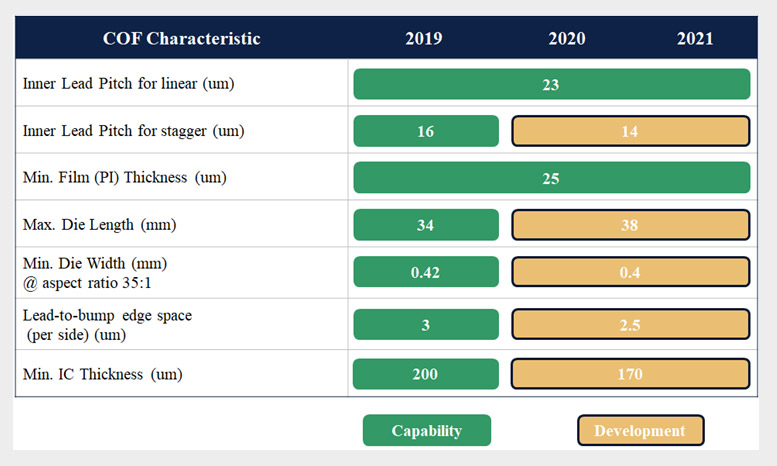

Process Capability & Design Rule

? ? COF

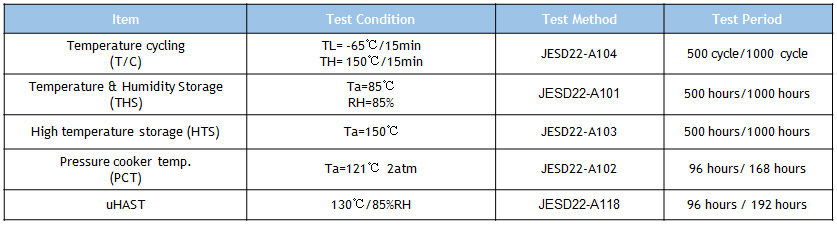

Reliability Test Standards

?

Shipment Packing

FCBGAFCLGA Series

Production Overview?

Flip Chip interconnection, also knownas Controlled Collapse Chip Connection, C4, has been identified as a high performance packaging solution to meet the growing need for products with increased electrical performance, high I/O, and high system reliability as a replacement for conventional wire bond process. Utilizing whole die area as for electrical connection, substrate I/O per unit exponentially increased vs. perimeter wire interconnection technology.?

Flip chip interconnect also allows direct connection with on-die power planes which enables increased electrical performance including increased switching speed and more efficient power distribution to the IC performance at lower operating voltages.?

TF-AMD Flip Chip are assembled with single unit laminate which is the highest routing density through build-up technology to maximize the device performance &conventional ceramic substrate for reliability enhanced package solution. Combined with Flip Chip interconnection, TF-AMD provides optimal design flexibility for final package design& product format to fit an end user requirement.?TF-AMD offers Flip Chip BGA packages with ball counts up to 3000 & PGA package up to 2000

Application?

Flip Chippackage is considered one of the most established industry platform applicable for high pincount and/or high performance ASICs. Large body FC BGA/PGAs provide package solution forComputing (microprocessors / graphic, server), gaming,high bandwidth networking/Communicationdevices. Combined with Flip Chip technology &BGA/PGAlead format, TF-AMD help to enable SMT and also pin insertion application.

Features?

Flip Chip BGA/PGA Packaging?

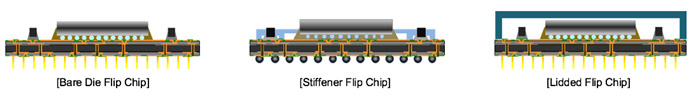

Package Types: Bare die, Stiffener, Lidded (Top hat & flat top)?

Wafer Node 314/16nm ELK(extreme low K) qualified, 7nm in development.?

Package sizes from 12mm to 55mm (75mm in development)?

Die area up to 800mm^2?

Lead Free, Eutectic, High-Pb bump for Flip Chip connection?

Passive component size down to 01005?

High thermal performance solution using Indium metal TIM?

Substrate?

? ? ? ? ? ? ? ?o? ? 4 – 18 layers laminate build up?

? ? ? ? ? ? ? ?o? ? Coreless, 0.2mm, 0.4mm, 0.8mm, 1.0mm available?

? ? ? ? ? ? ? ?o? ? High CTE ceramic / LTCC alumina ceramic?

? ? ? ? ? ? ? ?o? ? BGA / PGA?

Footprints Pitch?

? ? ? ? ? ? ? ? o? ? BGA : 0.5mm, 0.65mm, 0.8mm and 1.0mm?

? ? ? ? ? ? ? ? o? ? PGA : 1.0mm, 1.27mm?

Other Option?

? ? ? ? ? ? ? ? o? ? Multi-die capability?

? ? ? ? ? ? ? ? o? ? Die binning to waffle pack up to 256 BINs?

Flip Chip BGA/PGA Test?

Test Product Engineering?

? ? ? ? ? ? ? ? o? ? TF-AMD test provides a competitive test solution to our customers ranging from test development, platform conversion, and product maintenance and test data analysis.?

? ? ? ? ? ? ? ? o? ? The team has rich test development experience of various product portfolio, including high-end digital, mix-signal, SOC and high speed products.?

Adding Value to Customer?

? ? ? ? ? ? ? ? o? ? Reduce customer overhead by outsourcing projects / tasks to avoid maintaining a large scale of dedicated team?

? ? ? ? ? ? ? ? o? ? Incorporate industrial standard through leveraging best known method from our database & continuous cost saving by driving test time reduction, yield improvement?

Service Solutions?

? ? ? ? ? ? ? ? ?o? ? Wafer Sort test development?

? ? ? ? ? ? ? ? ?o? ? Final Test development?

? ? ? ? ? ? ? ? ?o? ? Low cost platform conversion?

? ? ? ? ? ? ? ? ?o? ? Multi-site enablement?

? ? ? ? ? ? ? ? ?o? ? Burn-in capabilities?

Test Development Experience?

? ? ? ? ? ? ? ? ?o? ? CPU, APU, GPU?

? ? ? ? ? ? ? ? ?o? ? Chipset?

? ? ? ? ? ? ? ? ?o? ? Digital Audio?

? ? ? ? ? ? ? ? ?o? ? Baseband?

? ? ? ? ? ? ? ? ?o? ? Microcontroller?

? ? ? ? ? ? ? ? ?o? ? LCD Driver?

? ? ? ? ? ? ? ? ?o? ? Touch Panel Driver?

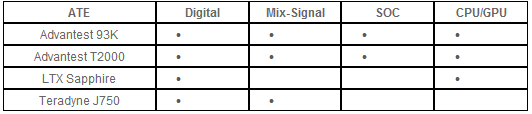

ATE platforms and products?

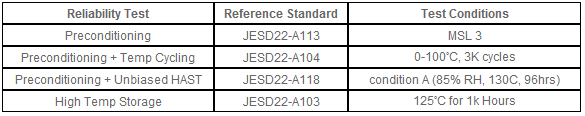

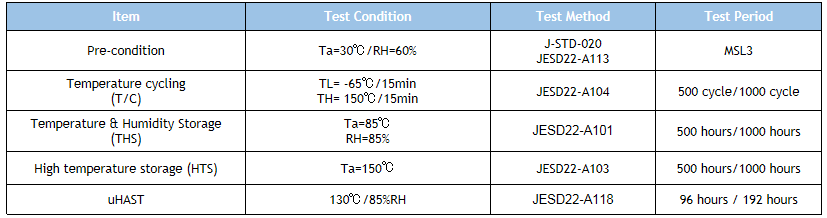

Reliability Test Standards?

Design Rule?

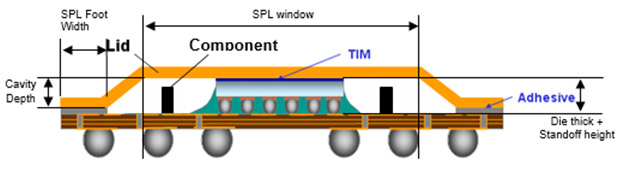

Top Hat Single Piece Lid?

Lid size=substrate size-0.2mm?

Standard foot sizes?

? ? ? ? ? ? ? ? ? ? ? ? o? ? 2mm for 15-25mm body?

? ? ? ? ? ? ? ? ? ? ? ? o? ? 3mm for 27-31mm body?

? ? ? ? ? ? ? ? ? ? ? ? o? ? 4mm for 33-50mm body?

Max 3mm on all four sides (UF will flow under the bend/slant of the HS). Extended design rule allow Max. 2.5mm for the body size ≤31mm?

Lid is centered?

Cavity depth for 12inch wafer SPL is 0.8mm and total thickness is 1.3mm?

? ? ? ? ? ? ? ? ? ?? ? ?o? ? TIM Thickness target: 40um (Max. 100um)?

? ? ? ? ? ? ? ? ? ? ?? ?o? ? Adhesive Thickness target: 120um (Max. 200um)?

? ? ? ? ? ? ? ? ? ? ? ? o? ? Lid manufacturing tolerance: +/-50um?

Body size<31mm support bare die structure (without stiffener/lid construction)?

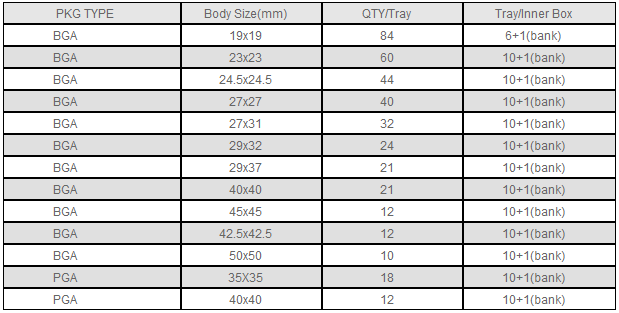

Packing & Shipping (in house standard)?

BGA / PGA (Tray)?

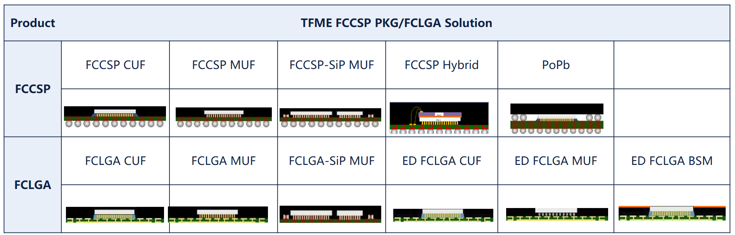

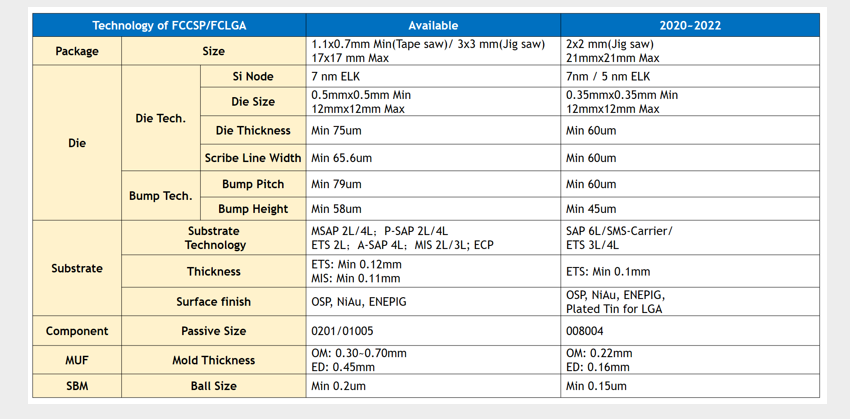

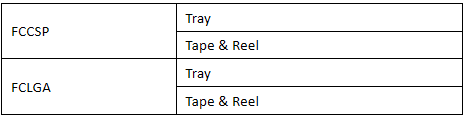

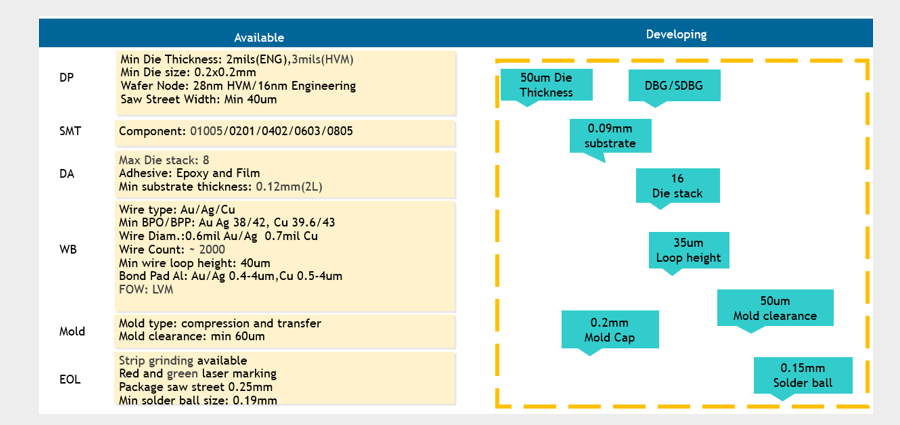

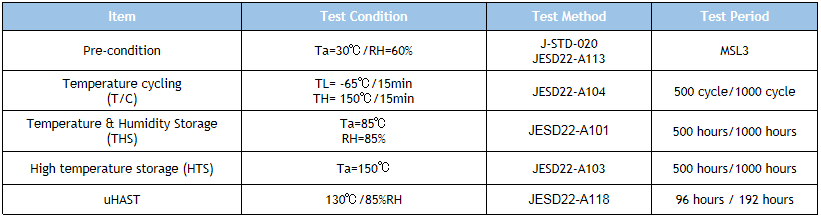

当前位置:首页?>?产品技术?封装品种?>FCCSPFCLGA Series Production Overview ? ? ? ? TFME offers various FCCSP and FCLGA package based on customer different requirement. Features Process?Capability & Design Rule Reliability Test Standards Shipment PackingFCCSPFCLGA Series

- SiP (FC + SMT + Wire bond) available.

- CUF, MUF available.

- 7N/12N/14N/16N wafer node mass production

- Various substrate technology qualified including SAP, MSAP, ETS, MIS and SLP.

- Fully Turnkey for wafer bumping, probing, assembly, FT available.

WBBGAWBLGA Series

Production Overview

? ? ? ? TFME offers various WBBGA and WBLGA package based on customer different requirement.

Features

- 1.1x0.7 mm to 21x21 mm Package

- 0.2mm to 1.0mm C Mold Chase

- 01005 Components SMT

- 0.3x0.3 mm Small Die?

- 1-6 Layer Substrate

Process Capability & Design Rule

Reliability Test Standards

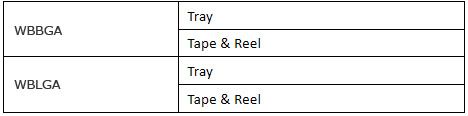

Shipment Packing